XINGDA Intelligent Cloud Platform:

Full digitization, Omni-perception and Interconnectivity

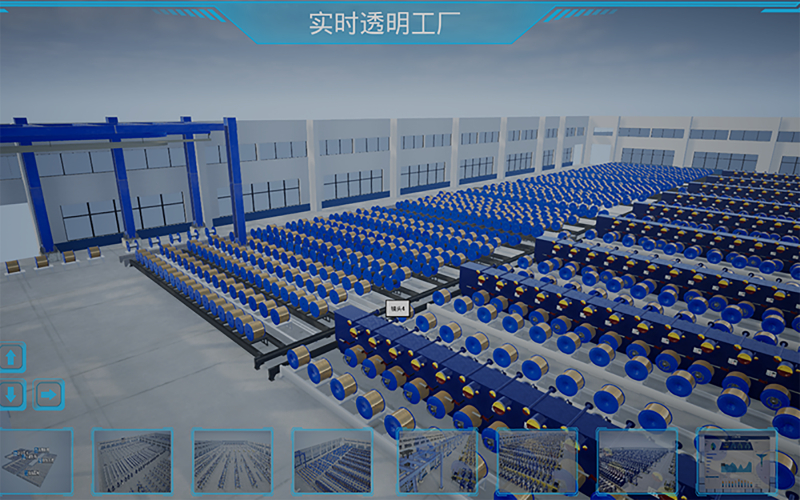

XINGDA Intelligent Factory:

Informatized, Smart, Automated and Transparent

Automatic production and intelligent control throughout the process

Transparent management of all the production processes

Today, XINGDA is standing at the forefront of the application of digital and intelligent technologies.

Ubiquitous connection of smart devices

Accurate delivery of products into warehouse

Real-time monitoring of production process

Bidirectional traceability of quality information

Intelligent control of energy consumption

Coordinated efforts to ensure safety and environmental protection

Smart factories empower enterprises

XINGDA Rubber Reinforcement Cloud

An Artificial Intelligence of Things (AIoT) Integrating the Upstream and Downstream of the Industry